When it comes to machining equipment, the term ‘lathe’ might often come up. If you have ever stepped foot into a machine shop, chances are you’ve encountered one of the most basic manual lathes. With numerous applications and indispensable functions, the lathe has held its place as a pivotal tool in the engineering world. But which is the most basic of the manual lathes? Lets explore this fundamental question and understand its implications for beginners and professionals alike.

Introduction to Manual Lathes

Manual lathes are among the earliest forms of machine tools, dating back several centuries. These lathes employ a simple mechanism for material removal, making them accessible for those embarking upon the journey of machining.

Beginners often start with basic manual lathes due to their simplicity and ease of operation. These machines equip users with foundational skills necessary for more advanced machining tasks.

Why Opt for Manual Lathes?

Despite technological advancements, manual lathes remain in use primarily because they offer unparalleled control and precision. They help users develop a true understanding of material behavior under machining conditions.

Additionally, these lathes allow for innovative experimentation and creativity, especially in small-scale production environments.

The Construction of Basic Lathes

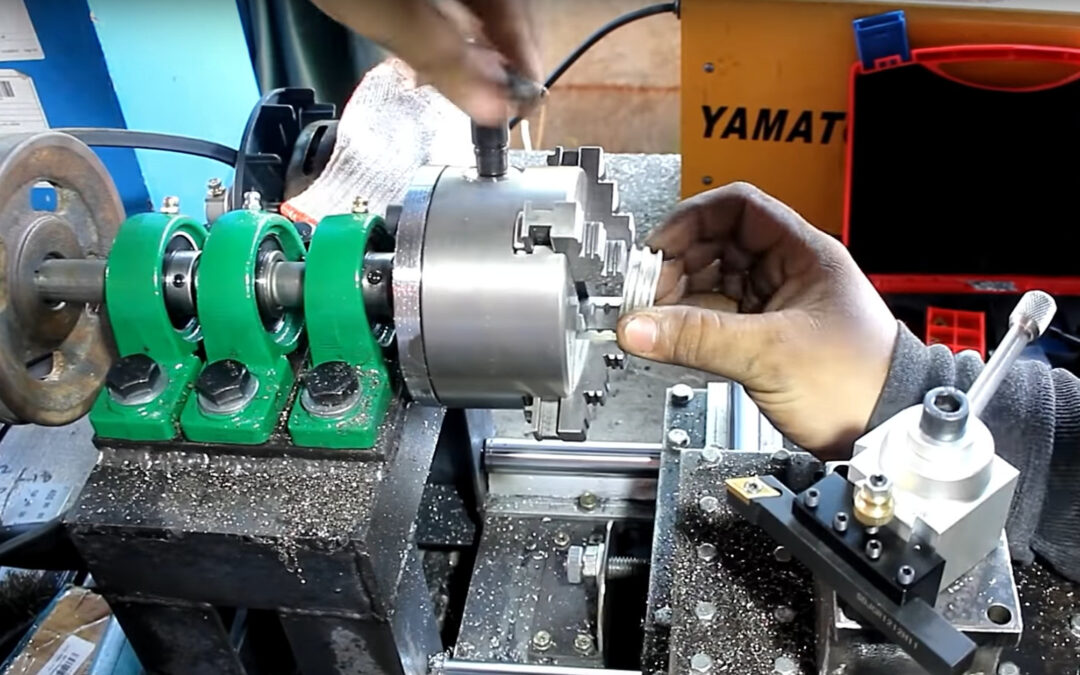

The average manual lathe typically consists of several fundamental components. These include:

- Headstock – The part that houses the spindle.

- Tailstock – Supports the other end of the workpiece.

- Carriage – Moves tools across the workpiece for cutting.

- Bed – Provides a solid foundation for the machine.

Differences Between Manual and Powered Lathes

There’s a certain charm in operating manual lathes that cannot be replicated by their automated counterparts. While CNC lathes provide speed and efficiency, manual lathes offer hands-on experience.

The tactile feedback received from manual lathes aids in developing a deeper understanding of the craft. Moreover, they serve as a cornerstone in vocational training, proof of which can be seen in their prevalent use, even to this day.

Step-by-Step Guide to Using a Manual Lathe

Setting Up the Lathe Properly

Correct setup is crucial for achieving accurate and consistent results. Ensure the machine is well-aligned and the tools are sharp and properly mounted.

As sensitivity is key in operations, your attention to detail will enhance the final outcome.

Basic Operations: Turning and Facing

With the setup complete, basic operations such as turning and facing can commence. This process involves removing material from the workpiece, shaping it to desired dimensions.

Understanding fundamental operations will enable machinists to build a solid foundation in machining basics.

Troubleshooting and Safety Measures for Manual Lathes

Common Issues and How to Fix Them

Manual lathes, like all machines, can confront issues such as tool wear or misalignment. Regular inspections and maintenance help keep these lathes in prime condition.

Equally important is comprehensive manual review to understand the quirks and nuances specific to each model.

Safety First

Safety protocols are paramount when operating powerful machines. Proper apparel, including eye protection and fitted clothing, must be worn consistently during machining operations.

Being vigilant and maintaining awareness helps prevent accidents, ensuring a safer shop environment for everyone involved.

Conclusion: The Enduring Appeal of Manual Lathes

In summary, the most basic of manual lathes remains a fundamental tool in both industrial and educational settings. Its role in building foundational machinist skills is unparalleled.

Despite the advent of advanced technology, manual lathes continue to serve as a valuable resource, fostering creativity, precision, and expertise for future generations of machinists.

FAQ

Is a manual lathe suitable for beginners?

Yes, it’s especially beneficial for beginners due to its simplicity and the foundational skills it imparts.

What materials can be machined on a manual lathe?

Manual lathes can work with a variety of materials, including wood, plastics, and metals, such as aluminum and copper.

How often should a manual lathe be maintained?

Regular maintenance such as cleaning and lubrication should be done routinely after every significant job to ensure longevity and safety.

This article contains affiliate links. We may earn a commission at no extra cost to you.