The question Where are Victor lathes made? often comes up, especially among those interested in industrial equipment and machinery manufacturing. Victor lathes have built a strong reputation for precision and durability in the machining world. But understanding their origin and production process is key to appreciating their value fully.

Originally, Victor lathes were crafted with meticulous attention to detail. Those looking to understand more about their origin often want to delve into the production ethos that makes these machines stand out. This exploration will not only reveal their geographical roots but also the philosophy behind their construction.

The Legacy of Victor Lathes

Victor lathes are renowned for their solid build quality and exceptional performance. Over the years, they have become synonymous with reliability and precision in the machining industry. This reputation is not simply because of good marketing but due to an unwavering commitment to quality.

Many entrepreneurs and business leaders who rely on machinery know the impact a reliable lathe can have on their bottom line. Ensuring that each model is engineered to exact specifications is a practice rooted deeply in Victors manufacturing tradition.

The Birthplace: Where It All Began

The question of where Victor lathes are made has a straightforward answer. These machines originate from Taiwan, a location recognized for its advanced manufacturing capabilities. Taiwan’s industrious landscape provides the perfect backdrop for producing high-precision equipment.

Victor Factory, the main production hub, employs skilled craftsmen and state-of-the-art technologies. Taiwanese manufacturers are known for their innovation and efficiency, contributing significantly to the global machinery market.

Taiwan’s Influence on Manufacturing

Taiwan stands as a beacon of high-quality production standards in the machinery sector. The country’s focus on research and development ensures that each Victor lathe is not only top-tier but also incorporates the latest technological advancements.

For those wanting to understand Victor’s quality assurance process further, it’s worth exploring Taiwan’s influence on machinery as a whole.

Engineering Excellence at Victor’s Facility

The manufacturing facility is equipped with the latest engineering tools and abides by stringent international standards to produce lathes that meet various industrial needs globally. This commitment ensures the machinery can withstand continuous use in demanding environments.

Victor employs a collaborative approach, bringing together experts in machining and engineering to keep their designs both innovative and functional.

A Closer Look at the Production Process

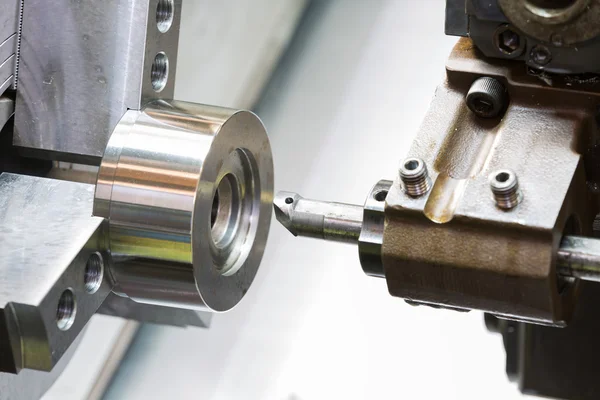

The production of Victor lathes involves several stages, each requiring meticulous oversight. From the initial design phase to final assembly, these machines are crafted with a focus on precision.

Design and Development

Every lathe starts as a concept, carefully crafted by a team of engineers. These experts pay close attention to industry trends to ensure the final product aligns with current demands and technological capabilities.

The result is a machine that is not only functional but also forward-thinking.

Assembly and Construction

The heart of the Victor production line is its assembly process, where each component is carefully installed by skilled workers. This step ensures that all parts fit together perfectly, enhancing the overall reliability of the machine.

The attention to detail during assembly is one of the reasons Victor lathes are favored by industries around the world.

Factors That Set Victor Apart

Several factors distinguish Victor lathes from competitors. These include not just the precise engineering and durable construction but also the companys commitment to customer satisfaction.

Emphasis on Quality and Innovation

Quality is at the forefront of Victors manufacturing ethos. Their commitment to customer satisfaction drives continuous improvement and innovation, ensuring that each machine is both efficient and user-friendly.

For those interested in how innovation impacts product development, consider exploring the journey of DripX’s product innovation to gain further insight.

Market Recognition and Client Base

Victor lathes enjoy widespread recognition, with a solid client base that spans various sectors such as automotive, aerospace, and manufacturing. Their reputation for robust performance makes them a go-to choice for professionals across industries.

The widespread use of these lathes is a testament to their reliability and the respect they command in the marketplace.

The Impact on Business Operations

Investing in a Victor lathe means investing in a machine that will support your business operations efficiently and reliably. This can lead to increased productivity and reduced downtime, both critical factors in maintaining a competitive edge.

For businesses exploring new avenues in operational efficiency, consider learning from innovative technologies in water management by reading about WaterXs revolution.

Why Choose Victor Lathes?

Choosing Victor lathes aligns you with a legacy of quality engineering. Their comprehensive support ensures that equipment remains at peak performance, minimizing disruptions in business operations.

This choice represents a commitment to longevity and performance, essential for long-term success in any industry.

Frequently Asked Questions

What makes Victor lathes stand out?

Victor lathes are renowned for their precise engineering, reliability, and the dedication to quality from their manufacturers in Taiwan.

Can I buy Victor lathes internationally?

Yes, Victor lathes are available internationally, with a distribution network that ensures global access to their high-quality machines.

How does Victor ensure quality?

Victor maintains rigorous quality assurance processes, ensuring each machine meets high standards before reaching the customer.

This article contains affiliate links. We may earn a commission at no extra cost to you.