Sharp lathes have become a cornerstone of modern machining, renowned for their precision, durability, and versatility. But a common question that arises among enthusiasts and professionals alike is, ‘Where are Sharp lathes made?’ Understanding the origins of these machines not only provides insight into their quality but also reveals the intricate process behind their manufacturing.

The Origins of Sharp Lathes

The journey of Sharp lathes begins in the bustling industrial landscape of Taiwan. Taiwan is well-regarded as a hub for high-quality machinery production. Over the years, Taiwan has garnered a reputation for producing reliable and efficient machine tools, making it an ideal location for the manufacturing of Sharp lathes.

Why Taiwan Is a Hub for Machinery

Taiwan’s rise in the machinery industry is no accident. Several factors contribute to its status as a global leader in manufacturing industrial tools:

- Skilled Workforce: Taiwan boasts a highly skilled workforce, specializing in precision engineering and manufacturing.

- Advanced Technology: The adoption of cutting-edge technology has enabled Taiwanese manufacturers to maintain high standards of quality in machinery production.

- Strong Supply Chain: Taiwan’s robust supply chain ensures a steady flow of raw materials and components necessary for producing machinery efficiently.

Distinct Features of Sharp Lathes

Understanding the features that set Sharp lathes apart will further illuminate why they are preferred by many professionals:

Precision and Accuracy

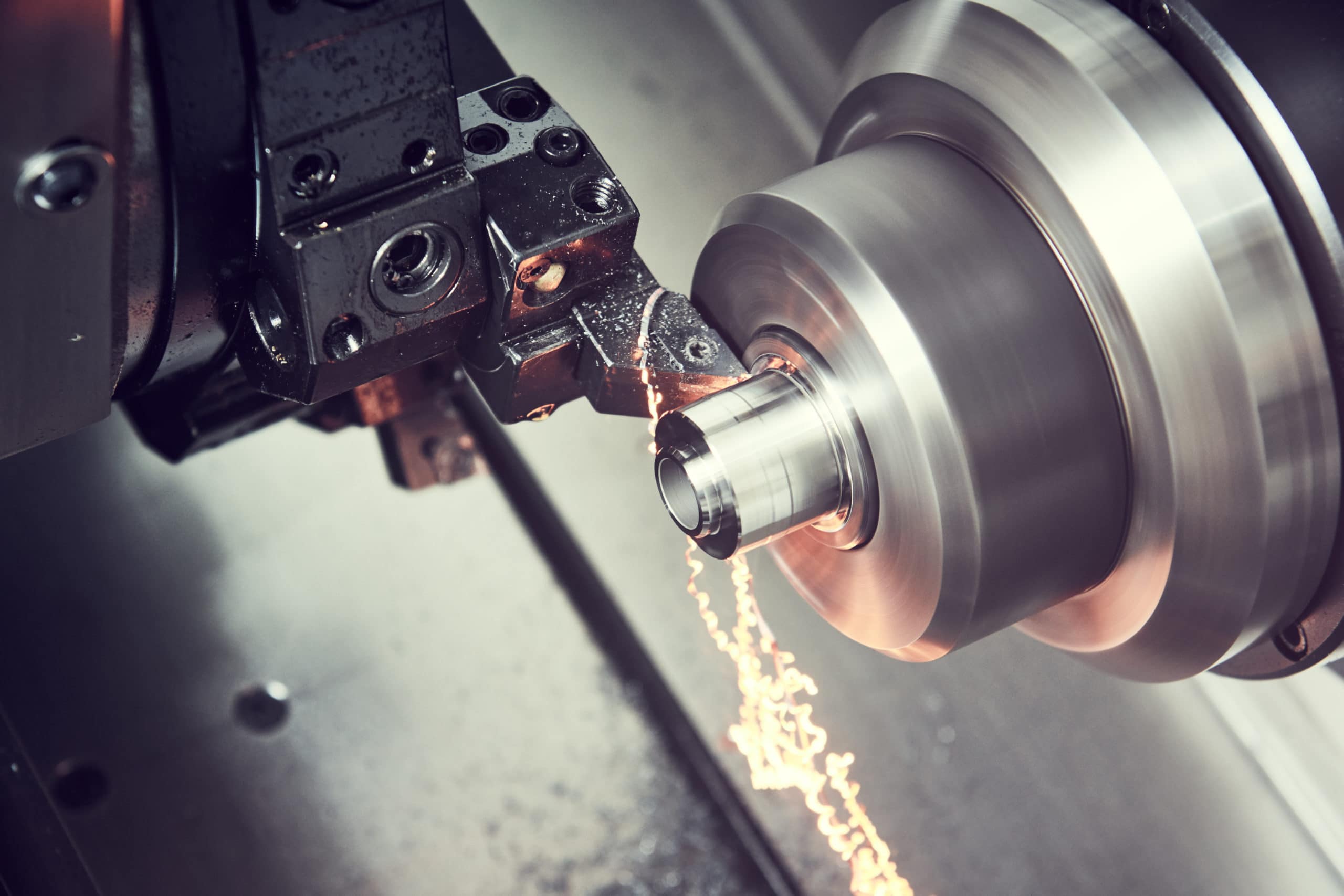

One of the defining characteristics of Sharp lathes is their unparalleled precision. These machines are designed to maintain tight tolerances, ensuring that each workpiece meets the exact specifications required by customers. This attribute makes them ideal for industries where precision is paramount.

Durability and Longevity

Another standout feature of Sharp lathes is their durability. Constructed with high-quality materials and engineered to withstand rigorous use, these machines have a long lifespan, making them a worthwhile investment for any workshop or factory.

The Manufacturing Process

The making of a Sharp lathe involves several intricate steps, each vital for the end products quality and functionality:

Design and Engineering

The design phase involves creating detailed plans and ensuring that every component is engineered to perfection. The use of sophisticated CAD software allows for precise modeling and simulations, minimizing errors during the production phase.

Component Production

Once designs are finalized, the production of individual components begins. This step involves using high-grade metals and alloys, coupled with sophisticated manufacturing techniques, to produce parts that meet strict quality standards.

Assembly and Quality Control

Assembly of the Sharp lathe is a meticulous process that demands attention to detail. Each component is carefully fitted to ensure flawless functionality. Rigorous quality checks are performed at various stages to ensure that each machine adheres to the highest standards.

Global Impact of Sharp Lathes

The widespread use of Sharp lathes has had a significant impact on numerous industries worldwide. These machines enhance productivity, improve precision in manufacturing, and reduce downtime, thus contributing to overall industrial growth.

Moreover, the global distribution network of Sharp lathes ensures that businesses in different regions have access to these high-quality machines, enabling them to compete internationally.

Conclusion

Understanding where Sharp lathes are made sheds light on the rigorous processes and high standards that define these exceptional machines. Originating from Taiwan, a recognized leader in machinery manufacturing, Sharp lathes continue to impress with their precision, durability, and technological advancement. For businesses and enthusiasts alike, investing in a Sharp lathe translates to enhanced capabilities and sustained efficiency in machining practices.

Further Resources

For more information on how precision machine tools like Sharp lathes are used, consider visiting this detailed blog. You might also find valuable insights in our article on the best drill press for the money.

FAQs

1. What are the primary uses of Sharp lathes?

Sharp lathes are primarily used for shaping metal or wood by revolving the material against a cutting tool. They are essential in manufacturing processes where precision and efficiency are required.

2. Why is precision important in lathe operation?

Precision is crucial in lathe operation because it ensures that parts are produced to the exact specifications required, which is vital in industries such as automotive and aerospace where even minor deviations can lead to significant issues.

3. How does the location of manufacturing influence lathe quality?

The location of manufacturing, such as Taiwan for Sharp lathes, often correlates with the quality due to the presence of skilled labor, advanced technology, and rigorous quality control procedures inherent to the regions manufacturing practices.

This article contains affiliate links. We may earn a commission at no extra cost to you.