When you come across the term ‘what lathes work on crossword clue,’ it might initially perplex you. Fortunately, this article aims to delve deep into this concept, providing clarity and understanding. Lathes are pivotal tools in the world of machinery and engineering, used to shape, cut, and manipulate material, both wood and metal.

For enthusiasts or professionals in the field, understanding the facets of a lathe is crucial. Knowing what lathes work on can enhance your craftsmanship, whether you’re shaping components for industrial needs or crafting custom pieces. Dive into our exploration, starting with the fundamental uses and types of lathes.

Understanding the Basics of Lathes

1. What is a Lathe?

A lathe is a sophisticated machine tool that rotates the workpiece on its axis, enabling various operations such as cutting, sanding, knurling, drilling, and turning. This machine plays an indispensable role in shaping objects, offering precision and adaptability in manufacturing.

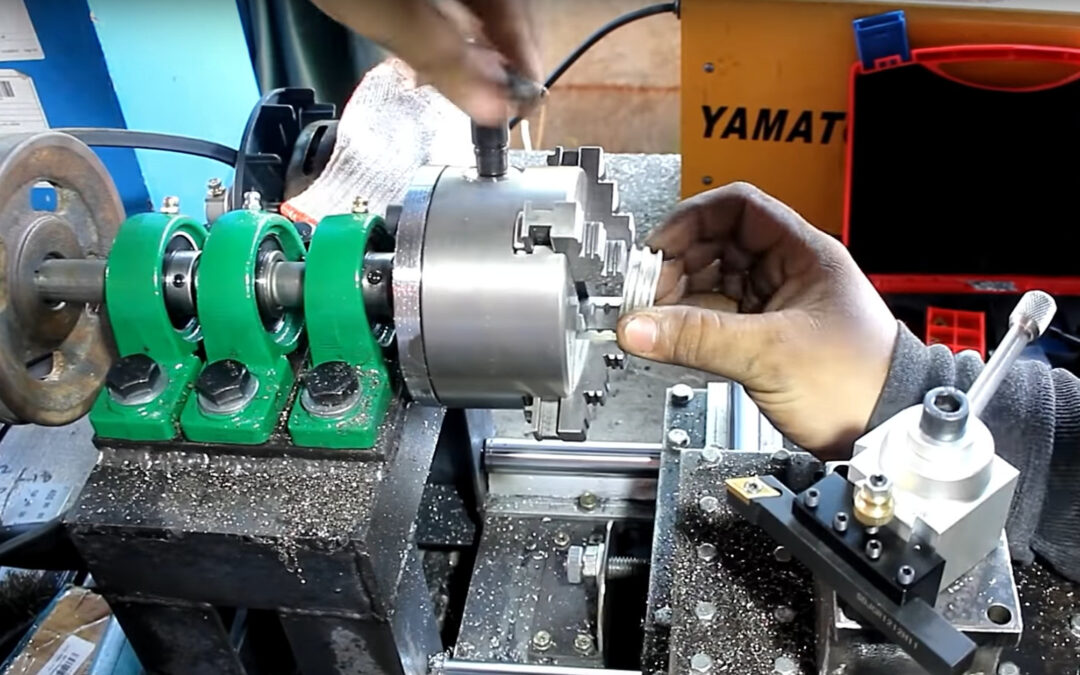

2. Key Components of a Lathe

Understanding the vital components is crucial. A typical lathe consists of the bed, headstock, tailstock, and carriage. Each part plays a role in ensuring accurate operation. Learn more about the specifics at Lathe Machine Details.

Delving Deeper into Types of Lathes

3. Engine Lathes

The engine lathe is perhaps the most common type, utilized widely for its versatility across different projects. Whether you’re working with metal or wood, engine lathes provide a robust foundation for craftsmanship.

4. Turret Lathes

Turret lathes streamline production due to their efficiency in machining different parts without the need to reset setups. They’re invaluable in bulk manufacturing setups.

5. CNC Lathes

Computer Numerical Control (CNC) lathes have revolutionized the field with their precision and programmability. They allow users to create complex shapes with minimal manual intervention, improving efficiency and accuracy.

Exploring Lathe Operations

6. Turning Operations

Turning is perhaps the most recognizable operation performed on lathes. It involves rotating a workpiece to achieve desired shapes or finishes. This operation is versatile, allowing for adjustments in dimensions and aesthetics.

7. Facing Operations

During facing operations, the lathe is utilized to cut a flat surface at the end of the workpiece, crucial for ensuring proper fit and finish in assemblies.

8. Taper Turning

Taper turning allows for the creation of conical shapes and is essential in designing precise objects like automotive parts. Understanding the intricacies of taper turning can significantly enhance the quality of your output.

Industry Applications of Lathes

9. Automotive Industry

In the automotive industry, lathes shape critical components like engine shafts and hubcaps. Their precision ensures these parts function optimally, enhancing vehicle performance.

10. Aerospace Industry

Aerospace applications demand high precision and reliability. Lathes contribute to producing components that meet stringent standards, ensuring safety and efficiency in flight.

11. Woodworking and Design

Lathes arent just limited to metals; they are essential in woodworking too, shaping everything from furniture legs to decorative pieces with intricate designs.

Challenges and Solutions in Lathe Operations

12. Precision Issues

Achieving the desired tolerance levels can be challenging. Utilizing modern technology and regular maintenance can help in maintaining precision over time.

13. Material Concerns

Different materials react distinctively to lathe operations. Understanding these nuances is necessary for selecting the appropriate setup and tools for each project.

Maximizing Productivity with Lathes

14. Maintenance Practices

Regular maintenance, including lubrication and alignment checks, is vital to prevent downtime and enhance the longevity of lathe machines.

15. Lean Manufacturing Principles

Incorporating lean manufacturing principles into lathe operations ensures minimal waste and maximizes productivity, offering competitive advantages. For more insights on optimizing machine use, check this resource on milling machine transport.

Conclusion: The Essential Role of Lathes

Lathes remain pivotal in various industries due to their ability to create a wide array of components. Whether you’re solving a crossword or shaping metallic or wooden pieces, understanding their operation is invaluable. From basic engine lathes to advanced CNC systems, they contribute immensely to modern engineering and craftsmanship.

FAQs

1. What materials can lathes work on?

**Lathes** can shape a variety of materials including metals, wood, plastics, and composite materials.

2. How does a CNC lathe differ from traditional lathes?

CNC lathes utilize computerized controls for precision and repeatability, differing from manual operation in traditional lathes.

3. Why is regular maintenance important for lathe machines?

Regular maintenance preserves the functionality and precision of **lathe machines**, ensuring long-term reliability and efficiency.

This article contains affiliate links. We may earn a commission at no extra cost to you.