When exploring the capabilities of drill presses, a fundamental question that arises is ‘what is the throat capacity of a drill press’? This term refers to an essential measurement that influences a drill press’s functionality and versatility within various tasks. Whether you are an enthusiast, professional craftsman, or someone curious about how machines like these work, understanding this concept is vital.

Definition of Throat Capacity

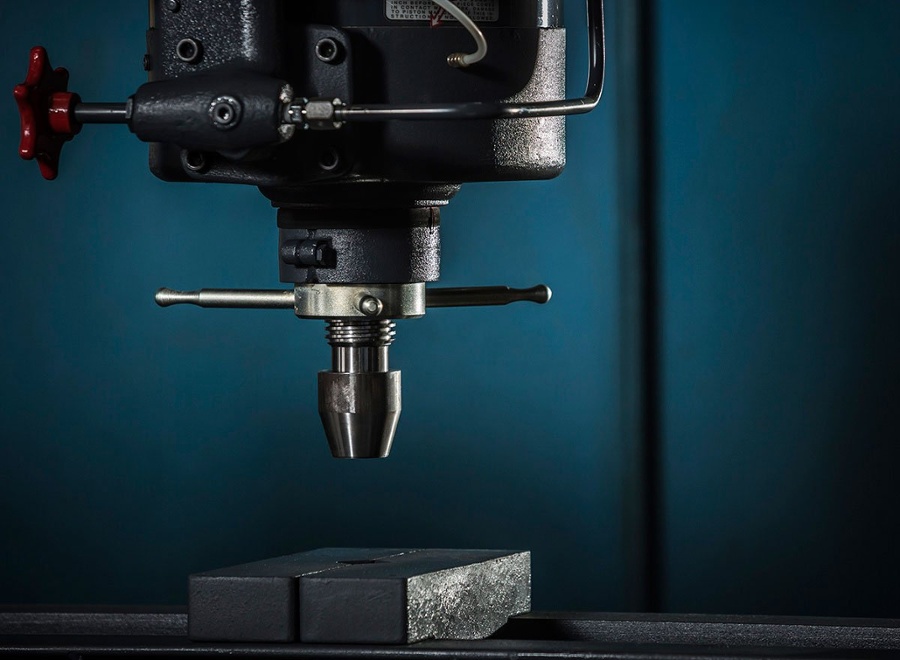

The throat capacity of a drill press is the distance between the drill bit and the column of the press. This defines the size of the material that can be moved under the drill bit without obstruction. For those unfamiliar, the column is the vertical support column from the base of the drill to the drill head, usually found at the back of the machine. This measure is crucial as it influences the scale of projects you can handle on this machine.

Why is Throat Capacity Important?

Having a clear understanding of the throat capacity can significantly affect your project outcomes. For instance, a larger throat capacity allows for broader or larger materials to fit under the drill bit, enabling work on bigger projects. This aspect becomes especially crucial in fields such as woodworking and metalworking, where the dimensions of the material often vary greatly.

Standard Throat Capacities

Throat capacities can vary significantly based on the model and intended use of the drill press. Common household drill presses typically range between 5 to 20 inches. Professional-grade models might offer even larger capacities to accommodate more diverse project requirements.

Comparing Different Models

Choosing the right drill press often depends on examining various models and their throat capacities. Models designed for heavy-duty tasks may feature extended columns that offer larger throat capacities necessary for specialized tasks.

Selecting the Right Drill Press

When deciding which drill press to purchase, two factors stand out: the size and the type of material you expect to encounter most in your work. For those questioning what size drill press might be suitable, assessing your most frequent projects can help streamline this decision.

Entry-level Models

Entry-level models typically have smaller throat capacities. These suit individuals pursuing smaller scale or simpler tasks. They provide a blend of compact design while still offering enough power for common projects.

Professional Use Models

Machines meant for professional environments often boast larger throats, increasing their functionality across varied tasks. Such models are ideal for advanced users who require more flexibility and power.

Impact on Precision

A higher throat capacity offers certain advantages but can impact the precision of your work. Ensuring congruency between the capacity and the accuracy requirements of your tasks is crucial. Assess whether the extra throat room will impede the intricacies of your detailed work. Read more about using drill presses for precision tasks in our guide on boring a cylinder.

Maintenance and Care

Regular upkeep of your drill press ensures that it continues to operate with optimal functionality. Throat capacity can sometimes be affected by equipment wear and long-term use. Following maintenance guidelines is key to preserving your machine’s integrity.

Regular Inspection

Inspect different parts for any signs of damage. Focusing on both mechanical and structural integrity can prevent costly repairs later on.

Lubrication

Keeping the moving parts well-lubricated is vital for maintaining the drills operational components. Follow the manufacturers guidelines for lubrication to preserve longevity.

Relevant Safety Measures

Though a drill press might seem straightforward to use, safety should never be underestimated. It’s essential to familiarize yourself with safety precautions related to designing operations to reduce hazards and enhance efficiency.

Optimizing Projects with Throat Capacity in Mind

Understanding throat capacity can truly enhance your productivity by aligning your projects with the capabilities of the machine. Dive deeper into project optimization at our guidebest drill press aimed for your budget.

Planning Your Work

Focus on pre-planning stages that require calculating dimensions and thorough material analysis to ensure they align perfectly with your drill press.

Project Varieties

Whether working on a detailed furniture piece or larger metal frameworks, throat capacity will determine your ability to execute tasks efficiently and without any hitches.

FAQ

- What does throat capacity mean? Throat capacity is the measurement signifying the distance between the drill bit and the drills column, affecting the size of material that can be processed under the drill bit.

- How is it measured? Its usually measured from the center of the chuck to the column, determining the swing size of the drill press.

- What are the best drills for throat capacity? Depending on your needs, professional models offer higher capacities, while standard models suit more basic tasks. Visit our guide on the best drill models for various functions.

This article contains affiliate links. We may earn a commission at no extra cost to you.