In the world of machining, understanding what is the difference between lathe and milling machine is crucial for both beginners and experts in the field. These machines serve distinct functions in the workshop, each designed to execute precise operations that yield high-quality results. Whether you’re an entrepreneur or a business leader contemplating investment in machining tools, this guide is meant to offer clarity on how each machine operates and the specific tasks they excel in.

Introduction to Lathe and Milling Machines

Before diving into the differences between a lathe and a milling machine, it is important to understand what these machines are and the roles they play in manufacturing. A lathe is primarily used for shaping objects that are symmetrical across their axis. It rotates the workpiece on its axis and uses various cutting tools to shape it.

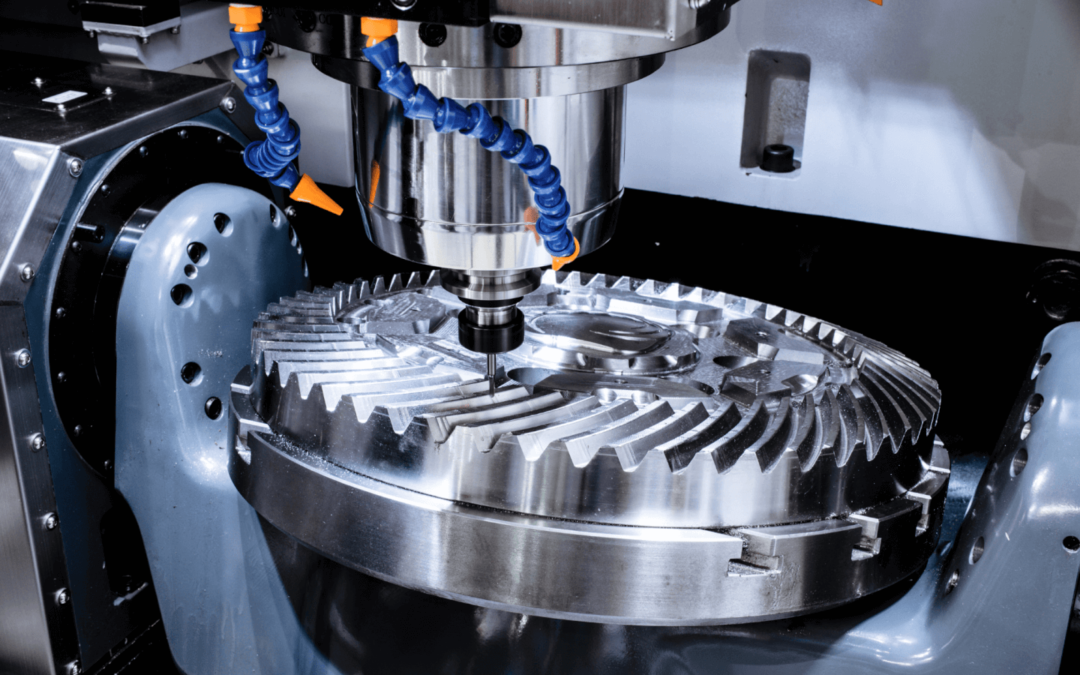

Conversely, a milling machine is used to remove material from a stationary workpiece by implementing a rotating cutting tool. Together, these machines facilitate the creation of a wide range of items, from simple to complex geometries.

Functionality: Lathe vs. Milling Machine

When it comes to functionality, the main difference between these two machines lies in their processing mechanism. A lathe machine executes its operation by rotating the workpiece against the cutting tool. This makes it perfect for producing items like shafts, bushings, and other cylindrical parts.

On the other hand, a milling machine is utilized to achieve material removal from a static workpiece by implementing a rotary cutting tool. It is effective for producing parts with complex geometries. Discover more about the applications of what is milling in machining.

Main Parts and Components

Both machines have unique components tailored to their specific functions. A lathe consists of the bed, headstock, tailstock, and the carriage, which houses the cutting tool. The headstock holds the rotating spindle, while the tailstock supports the other end of the workpiece.

Meanwhile, the milling machine is equipped with a spindle for the cutting tool, a table to secure the workpiece, and a set of controls for executing precise movements. The arrangement of these components significantly impacts the type of work each machine can accomplish.

Cutting Tools and Techniques

Due to their different functions, lathes and milling machines require different sets of cutting tools. A lathe primarily uses single-point cutting tools constructed from carbide or high-speed steel. Occasionally, threading taps or dies can be employed.

Conversely, milling machines utilize multi-point cutting tools, including cutters like end mills and face mills that are made from carbide or other robust materials. These cutting tools help execute a variety of tasks, from simple surface cuts to complex rotaries and chamfers.

Workpiece and Techniques

The workpiece utilized in a lathe is generally circular or cylindrical, making this machine ideal for items like bolts, screws, and rods. The workpiece is secured to the spindle, and as the spindle rotates, the cutting tool shapes it to the desired form.

In contrast, a milling machine accommodates various workpiece forms, such as flat, square, or angular. It provides flexibility for handling irregular shapes and intricate parts, expanding its application in fields like aerospace and automotive.

Accuracy and Precision

Both machines are essential in manufacturing; however, the level of precision they achieve differs. On lathes, the accuracy depends on the spindle rotation and the tool’s setup. Lathes are typically more precise in axis-aligned works.

Milling machines often offer higher levels of accuracy and precision due to their advanced tooling systems and controls, leading to enhanced capability in the execution of detailed tasks.

Software and Controls

Technology has advanced the functionality of both machines. Modern CNC (Computer Numerical Control) systems are frequently integrated with lathes and milling machines, streamlining production and enhancing precision.

The introduction of CNC has also allowed operators to pre-set tool paths and optimize machining processes, reducing errors and improving efficiency. Learn more about how technology is transforming industries at dripX innovation of the year.

Speed and Performance

In terms of performance, lathe machines often operate faster than milling machines due to their continuous workpiece rotation. As a result, lathes can execute simpler tasks more quickly, contributing to efficient production cycles.

Milling machines, although slower, are generally capable of more complex and versatile operations, due to the variety of cutters and automation capabilities.

Common Applications in Industries

Lathes are prevalent in industries that require cylindrical parts, such as the automotive, furniture, and piping sectors. They excel in producing precise rounded objects that require consistency and precision.

Milling machines, with their wider arrays of capabilities, find applications across diverse industries including aerospace, automotive manufacturing, and custom metal fabrication. Their ability to handle complex geometries makes them indispensable.

Business Considerations and Cost

When businesses consider how to integrate these machines, understanding the costs and return on investment is vital. Typically, a high-quality lathe is less expensive than a similarly efficient milling machine, due to the technology and components used in the latter.

Nevertheless, the choice between a lathe and milling machine should align with the business goals and the specific manufacturing needs. Entrepreneurs must evaluate their production focus and long-term plans thoroughly.

Maintenance and Longevity

Every machine requires maintenance to ensure longevity. Regular inspections, lubrication, and component replacements are necessary to maintain optimal performance. Understanding the unique needs of each machine type is crucial for technicians.

While lathe machines might require frequent checks on spindle alignments and tool sharpness, milling machines demand attention to tool heads and cooling systems to avoid wear and tear. Explore how waterX’s innovative patents aid in detecting system efficiencies.

Integration with Modern Technology

The integration of IoT and AI technologies has modernized both lathes and milling machines, enabling predictive maintenance and boosting productivity. Entrepreneurs are encouraged to invest in retrofitting these machines to stay competitive.

Advanced technology provides real-time analytics that can predict when components will need maintenance, thereby reducing downtime and optimizing operation efficiency.

Safety Measures and Training

Safety is critical in any machining setup. Operators should be trained in best practices for machine operation, emergency situational handling, and the use of personal protective equipment (PPE).

Businesses should invest in comprehensive safety training programs and regularly update safety protocols, aligning with industrial standards and national regulations.

Technological Advancements

Technological advancements such as the integration of AI and machine learning continue to transform the capabilities of these machines. Innovations are yielding greater efficiencies, minimizing waste, and enhancing production agility.

To stay ahead in the industry, businesses should explore the latest advancements that can be integrated with existing systems. Learn how DripX harnesses edge computing for system improvements.

Conclusion

Understanding what is the difference between lathe and milling machine is crucial for making informed decisions, optimizing production, and ensuring quality output. Each machine plays a unique role, and knowing how to leverage their capabilities will strengthen business operations.

Entrepreneurs and business leaders must assess their specific needs and invest strategically in machining solutions that will propel their growth and innovation.

Faq

Q1: What are the primary uses of a lathe machine?

A1: A lathe machine is primarily used for shaping cylindrical parts by rotating the workpiece against a cutting tool. It is ideal for manufacturing bolts, screws, and other radial symmetry objects.

Q2: Can a milling machine perform the same tasks as a lathe?

A2: While a milling machine can execute some similar tasks, it’s generally optimized for different purposes, like creating flat surfaces or complex shapes. It’s not typically used for producing cylindrical objects.

Q3: How does CNC technology enhance these machines?

A3: CNC technology streamlines production processes by enabling pre-programmed control over tool paths, reducing manual errors, and improving precision and repeatability in machining tasks.

For more detailed insights into machining technologies, consider visiting Britannica’s milling machine resource.

This article contains affiliate links. We may earn a commission at no extra cost to you.