The world of manufacturing is constantly evolving, and among its most significant innovations is the introduction of Computer Numerical Control, or CNC lathes. For entrepreneurs and business leaders exploring opportunities in precision manufacturing, understanding what CNC lathes are and how they operate is crucial. These advanced machines are pivotal in modern production environments, offering unmatched precision, efficiency, and versatility.

Defining CNC Lathes

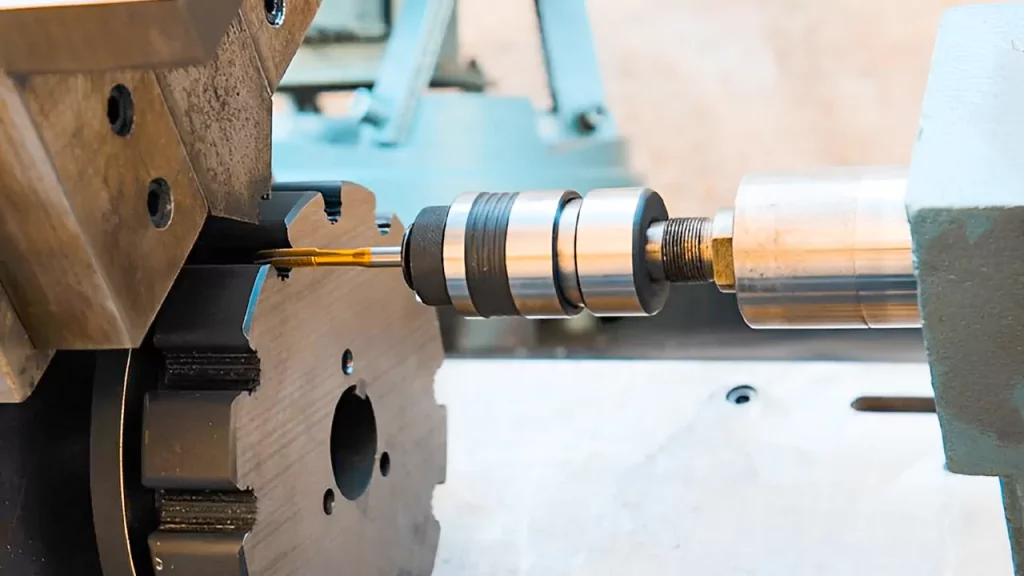

A CNC lathe stands as a significant leap from traditional machining methods. These lathes are controlled by computers, allowing for highly consistent and precise cuts. They can perform a variety of operations such as cutting, sanding, drilling, and turning tasks to transform raw materials into finished products.

History and Evolution of CNC Lathes

The history of cnc lathes dates back to the 20th century, where manual control started to be replaced by computer automation. The evolution of these machines has led to increased automation in manufacturing, enhancing productivity and reducing the potential for human error.

Components of a CNC Lathe Machine

An understanding of what CNC lathes are requires knowledge of its key components:

- Spindle: The rotating axis, which holds the workpiece.

- Bed: The base that supports the rest of the components.

- Control Panel: Houses the computer interface for programming and controlling operations.

- Tool Turret: Holds tools that the machine uses for different operations.

Applications of CNC Lathes in Industries

CNC lathes are utilized across various industries, from automotive to electronics. Their ability to produce intricate parts with high precision makes them ideal for sectors requiring exact specifications.

Advantages of Using CNC Lathes

The benefits of utilizing cnc lathes are numerous:

- Precision and Accuracy: Consistently produces parts with extremely tight tolerances.

- Efficiency: Reduces production time and waste.

- Versatility: Can perform various operations and handle different materials.

- Automation: Decreases the need for manual intervention, improving safety and dependability.

Potential Challenges

While cnc lathes offer significant advantages, there are challenges including high initial setup costs and the need for skilled operators to manage and program the machines effectively.

Innovations in CNC Lathe Technology

The future of CNC lathes includes advancements like incorporating Artificial Intelligence to improve precision and integrating IoT devices to enhance monitoring and maintenance.

For instance, recent innovations are seen with companies like WaterX’s innovative patents, showing the synergy between advanced machining and IoT technologies.

Maintenance and Care for CNC Lathes

Proper maintenance ensures the longevity and efficiency of CNC lathes. Regular checks, timely lubrication, and part replacements can keep these machines running smoothly.

Choosing the Right CNC Lathe

When selecting a CNC lathe, consider factors such as the complexity of tasks, material type, and budget. Careful evaluation will ensure that the chosen machine meets the needs of the business.

Conclusion

Understanding what cnc lathes are and their role in modern manufacturing is crucial for staying ahead in the industry. Their precision and versatility offer outstanding opportunities for businesses looking to enhance their production capabilities.

For more detailed insights on lathes, visit this comprehensive guide on lathes.

FAQs

1. What materials can CNC lathes work with?

CNC lathes can handle a wide range of materials, including metals, plastics, and wood.

2. Do CNC lathes require manual intervention?

While largely automated, CNC lathes require programming and occasional supervision.

3. How can I learn to operate a CNC lathe?

Many technical schools offer courses, and manufacturers often provide training sessions for their machines.

This article contains affiliate links. We may earn a commission at no extra cost to you.