In the ever-evolving world of manufacturing and entrepreneurship, understanding what you can make with a milling machine is essential. Milling machines, versatile in their function and capabilities, are indispensable tools that entrepreneurs, especially in the manufacturing and engineering sectors, can leverage to create remarkable products. In 2024, the possibilities are vast and exciting, and this guide will walk you through the potential of these amazing machines.

The core focus here is to explore the numerous applications and possibilities that milling machines offer. As technology continues to advance, so do the capabilities of milling machines, allowing for even more precision and diversity in manufactured products. Let’s dive into the world of milling machines and uncover their potential.

Understanding Milling Machines

A milling machine is a tool in the manufacturing industry that uses rotary cutters to remove material from a workpiece advancing in a direction at an angle with the axis of the tool. It’s a vital piece of equipment for creating parts and pieces of varying shapes and sizes. Milling machines are not just for creating planes and surfaces; they also help in forming holes, slots, and even complex geometries.

Curious to learn more about the different types of milling machines and how they function? A comprehensive guide on types of milling machines can enlighten you on their applications.

Types of Milling Machines

Vertical Milling Machines

Vertical milling machines have a vertically oriented spindle, which allows for greater control when making intricate cuts and shapes. They are widely used in the manufacturing industry for tasks that require precision and high-quality output.

Horizontal Milling Machines

The spindle in a horizontal milling machine is placed horizontally, making it more suitable for heavy-duty work where material needs to be removed quickly.

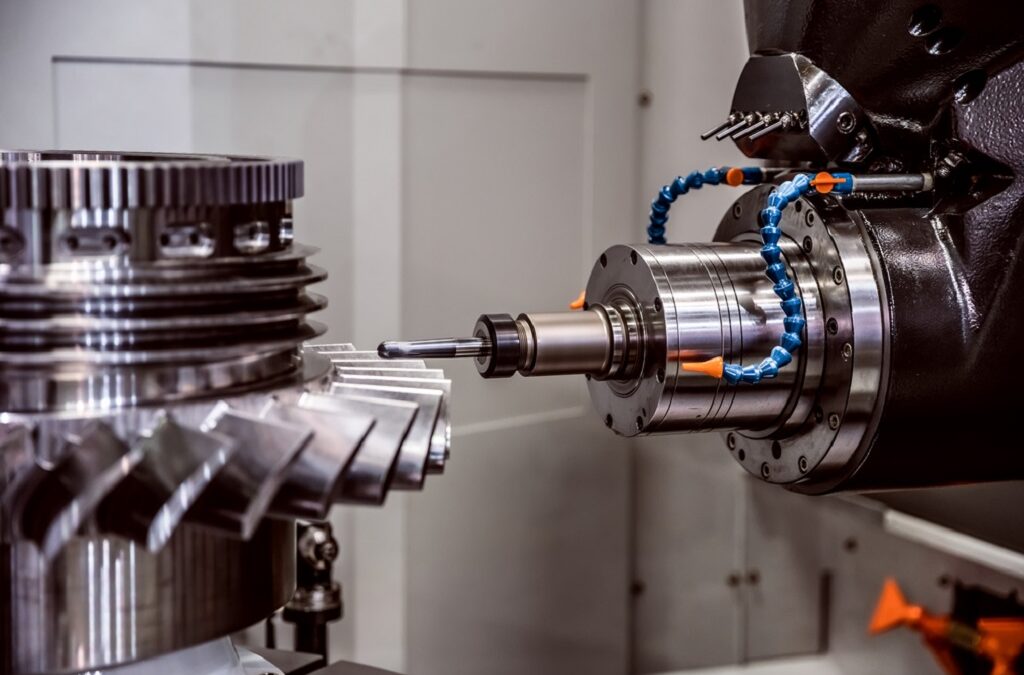

CNC Milling Machines

CNC (Computer Numerical Control) milling machines are equipped with a computerized system, enhancing accuracy and precision. They are perfect for producing complex parts efficiently, crucial for businesses aiming to scale up production. Interested in learning how to move this [machine](https://nolix.ai/how-to-move-a-milling-machine)?

What Products Can You Make?

Custom Automotive Parts

The automotive industry greatly benefits from milling machines. Entrepreneurs can design and manufacture custom parts like gears, engine blocks, and more, catering to specialized demands.

Prototyping and Product Development

Milling machines are instrumental in the prototyping phase of product development. Whether it’s a new gadget or component, precise models can be crafted, revolutionizing how new products are brought to market.

Furniture Components

With the ability to create precise joints and intricate designs, milling machines are widely used in producing high-quality furniture components. Wood machining allows for artistic creations too.

Aerospace Parts

The aerospace industry relies on high precision and durable components, which are efficiently produced using CNC milling. Quality is non-negotiable in this sector.

Electronic Enclosures and Components

With the rise of electronics, enclosures for components have seen a burgeoning demand. Milling machines help create sleek and protective housing for these delicate parts.

Innovative Uses of Milling Machines

Artificial Implants and Medical Devices

Milling machines allow the creation of high-precision medical devices such as implants, using materials like titanium and other alloys, pivotal to modern medicine advancements.

Jewelry and Artistic Sculptures

Entrepreneurs in the arts can leverage milling machines to craft beautiful and intricate jewelry and sculptures with precision cuts and designs.

Environmental Engineering Projects

In sectors focusing on sustainability, milling machines have been used to create components for environmental engineering projects aimed at energy efficiency and waste reduction.

Benefits of Using Milling Machines

Cost-Effective Production

By using milling machines, businesses can save on production costs due to the reduction in labor and material wastage.

Time Efficiency

Milling machines significantly reduce the time taken to produce components owing to their automation and high speed.

Milling Machine Safety Tips

Operating a milling machine requires attention to safety. It’s vital to follow guidelines such as wearing appropriate gear, understanding the machine, and keeping your workspace tidy. For more safety tips, you might want to visit a guide on milling safety.

Key Considerations Before Investing

Budget Analysis

Evaluating the cost against the potential ROI is crucial. Entrepreneurs should consider the long-term benefits of incorporating milling machines into their production process.

Training and Expertise

Having adequately trained personnel can leverage the full capabilities of milling machines. Training investments are as crucial as the machine itself.

Future of Milling Machines

As technology progresses, we can anticipate even more advanced and user-friendly milling machines. The integration with AI and IoT will likely play a significant role in future enhancements, making them smarter and more efficient.

Resources for Milling Machine Enthusiasts

For individuals interested in deepening their understanding of what they can create using milling machines, participating in online forums, communities, and attending workshops can be invaluable resources. There are many online guides and tutorials that can offer comprehensive insights into this field.

Conclusion

Understanding what can you make with a milling machine opens up a realm of possibilities in various industries. From creative artisan works to complex industrial components, the diversity is expansive. Entrepreneurs can harness these machines to not only create high-quality products but also drive innovation and efficiency in their businesses. As we stride into 2024, the potential for milling machines continues to grow, promising exciting opportunities ahead.

FAQs

What industries benefit most from milling machines?

Industries such as aerospace, automotive, electronics, and even furniture manufacturing greatly benefit from milling machines due to their capability to produce precise and intricate parts.

Can hobbyists use milling machines effectively?

Absolutely! Many hobbyists find value in using milling machines for projects like crafting custom parts for personal gadgets or artistic endeavors.

How do I choose the right milling machine for my business?

It depends on your specific needs and budget. Consider the type of products you plan to create and the scale of your production. Visiting sites for detailed reviews such as drill press guides can also aid your decision-making process.

This article contains affiliate links. We may earn a commission at no extra cost to you.