The question ‘what are lathes used for’ is one that draws curiosity especially from entrepreneurs and business leaders eager to understand their potential. Lathes are paramount in shaping the world’s infrastructure, bringing a vivid illustration of innovation and mastery in engineering processes. In fact, these versatile machines are not just about cutting or shaping but are gateways to unleashing unparalleled creativity across various domains.

Often perceived as a tool limited to metalworking, lathes have transcended those boundaries, becoming indispensable in industries like woodworking, pottery, and even the creation of intricate musical instruments. Their role in the rapidly advancing manufacturing world is expanding, promising endless possibilities for *technological advancement*.

1. Introduction to Lathes

At the heart of most production settings is the lathe machine. While rooted in history, it remains crucial in today’s industrial environment, having evolved far beyond its original scope.

2. Primary Components of a Lathe

A typical lathe consists of the bed, headstock, tailstock, carriage, and various other moving components. Understanding these parts is essential to grasp how they contribute to the machine’s functionality.

2.1 The Bed

The bed is the foundation of the lathe, providing stability and support to all other parts.

2.2 Headstock

Houses the spindle, which rotates the workpiece.

2.3 Tailstock

Supports the other end of the workpiece and can hold drilling or reaming tools.

3. Types of Lathes and Their Uses

In exploring different types of lathes, we see the technology is as diverse as it is intricate, from wood lathes to metal lathes, and their applications range across multiple industrial domains.

3.1 Wood Lathes

Used to create beautiful wood pieces like furniture and decorative items.

3.2 Metal Lathes

Essential for creating complex metal parts in industries such as automotive and aerospace.

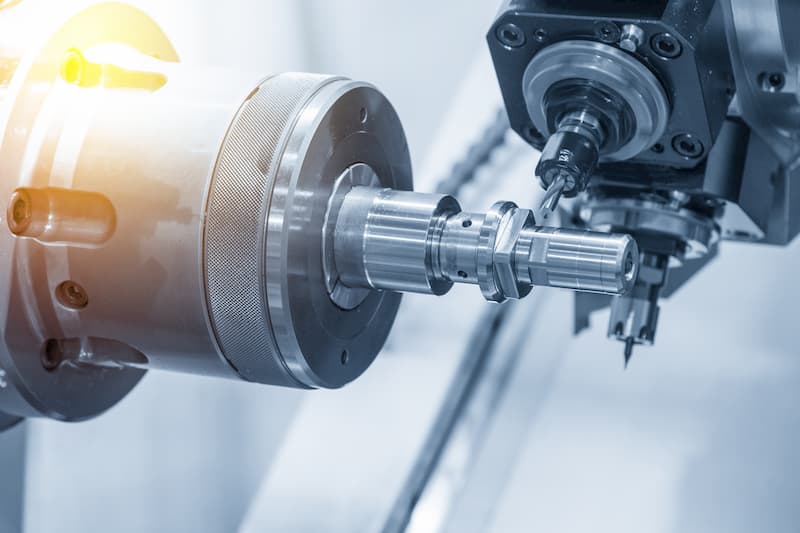

3.3 CNC Lathes

These modernized versions provide precision and automation, handling complex requirements.

4. Various Applications Across Industries

The wide-ranging applications of lathes showcase their adaptability. From creating intricate designs in woodcraft to developing precise mechanical components, their potential is boundless.

4.1 Automotive Industry

Vital for producing engine parts, axles, gear blanks, and even decorative motifs.

4.2 Aerospace Components

The precision offered by modern lathes allows for manufacturing lightweight yet durable aircraft parts.

5. Innovations in Lathe Technology

The world of lathes has witnessed remarkable innovations, influenced by edge computing advancements. With an urge for efficiency and precision, these innovations underline the industry’s progression toward automation and sustainability.

5.1 Digital Monitoring and Control

Modern lathes feature complex digital controls, enhancing precision and reducing the margin of error.

5.2 Energy Efficient Designs

Incorporating energy-saving technologies makes them fit well within sustainable practices.

6. Safety Measures and Best Practices

Safety remains paramount in any industrial setting. Implementing rigorous safety protocols when working with lathes ensures both machine longevity and workforce welfare.

6.1 Regular Maintenance

Ensures the lathe operates smoothly and reduces risks of malfunction.

6.2 Proper Training

Ensures operators are well-versed in handling machinery safely.

7. Future Prospects for Lathe Machinery

As technology advances, lathes promise continued significance. They will evolve to meet future needs, potentially incorporating new manufacturing processes.

FAQs

What are the main types of lathes?

Wood lathes, metal lathes, and CNC lathes are some prevalent types, each serving specific functions.

How does a lathe work?

A lathe rotates the workpiece against a cutting tool, allowing for precise material removal and shaping.

What industries rely heavily on lathes?

Automotive, aerospace, watchmaking, and musical instrument manufacturing heavily rely on lathes.

This article contains affiliate links. We may earn a commission at no extra cost to you.