Are you looking to learn how to mill without a milling machine? You’re in the right place! Many entrepreneurs and business leaders have sought cost-effective and innovative approaches for various engineering solutions. Milling, traditionally performed by a milling machine, can be daunting due to the required investment in equipment. But worry not, as this guide offers practical insights into milling without investing in a full-scale milling machine.

The art of milling involves removing material from a workpiece to achieve desired shapes and sizes. While typical milling processes employ large and expensive machines, understanding how to mill without a milling machine opens up possibilities for creators, businesses, and DIY enthusiasts to innovate efficiently. From manual techniques to digital tools, let’s explore alternative methods that make this process accessible to all.

1. Manual Milling Techniques

One of the simplest ways to mill without a machine is through manual methods. By employing files, chisels, or hand saws, one can gradually shape the material to the required specifications. This process requires a keen eye, patience, and steady hands.

Using Files and Rasps

Files and rasps are essential tools for anyone interested in manual milling. They allow you to precisely remove small amounts of material. It’s critical to select the right type of file for the specific job to maintain accuracy and efficiency.

Benefits of Manual Techniques

Manual milling gives you full control over the process and is cost-effective since it requires few tools. It fosters creativity and innovation, crucial for entrepreneurs looking for unique solutions without heavy investment.

2. Utilization of Drills

Drills are often underestimated in their ability to perform milling functions. By using various attachments, you can convert a simple handheld drill into a milling tool to manage less complex jobs.

Drill Press Setup

Setting up a drill press can turn a drill into a more stable milling device, allowing for precision and steadiness. Using end mills or wood routers, you can replicate some milling tasks conveniently.

Innovation of the Year offers further insights into clever tool adaptations.

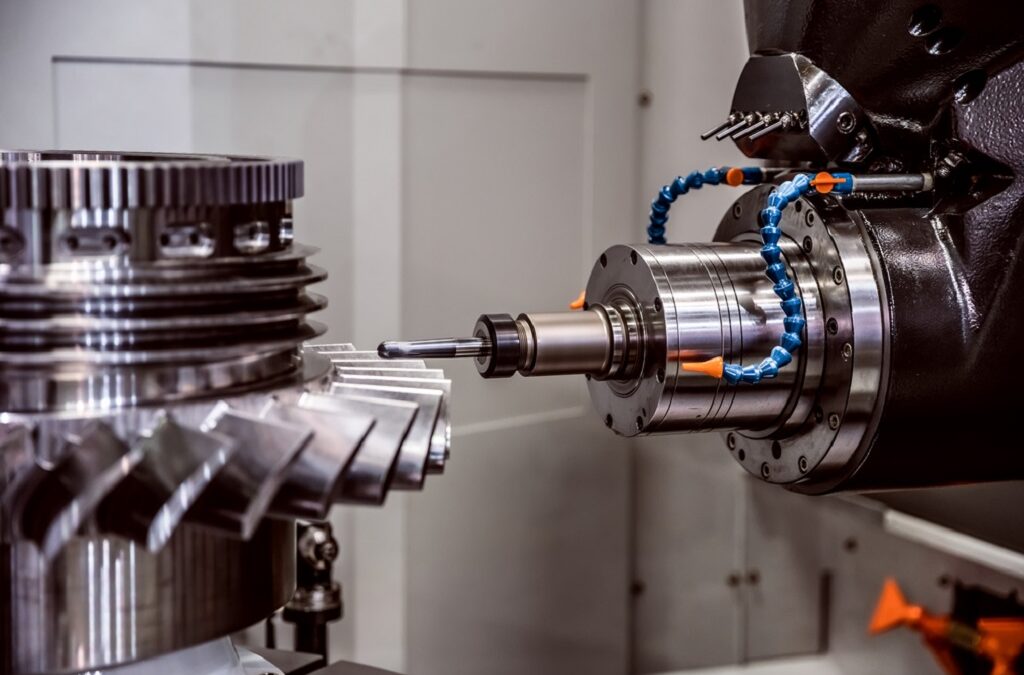

3. Innovative Use of CNC Routers

A CNC router is a versatile machine that can mimic milling processes. Utilizing affordable and compact CNC routers enables precision tasks without needing a full-fledged milling machine.

Utilizing CAD Software

Designing with CAD software and employing CNC routers allows you to achieve detailed tasks with minimal manual effort. CAD/CAM technology is exceptionally accessible and enhances the accuracy of cuts and shapes.

4. Employing Lathe Machines

A lathe machine is another potential substitute for a milling machine. Lathes work by rotating the workpiece against a fixed cutting tool, suitable for creating symmetrical shapes.

Adapting Lathes for Non-symmetrical Objects

While primarily used for symmetrical designs, lathes can be creatively adapted to perform milling functions on various materials. Understanding how to manipulate the tool position effectively broadens their utility.

5. Digital Milling Alternatives

The advent of digital milling alternatives has initiated a new era of precision and efficiency with minimal manual intervention. Technologies such as 3D printing have contributed significantly to this evolution.

Learn about milling machines to understand different processes and alternatives.

3D Printing as a Milling Substitute

3D printing shapes materials layer by layer, offering extreme precision. This technology is evolving fast, offering creative possibilities for businesses and hobbyists keen on trying something new.

6. FAQs

What is the cheapest way to start milling?

Manual methods using files and rasps are the most economical options to begin milling without significant investments.

Can a drill perform milling tasks effectively?

Yes, by using various attachments and a drill press setup, drills can handle simpler milling tasks effectively.

Are digital milling alternatives like 3D printers expensive?

3D printers vary in price, but affordable models are available for business leaders and entrepreneurs seeking innovative solutions.

For more comprehensive insights, consider exploring resources like WaterX Patents that inspire invention and efficiency in operations.

This article contains affiliate links. We may earn a commission at no extra cost to you.