Introduction

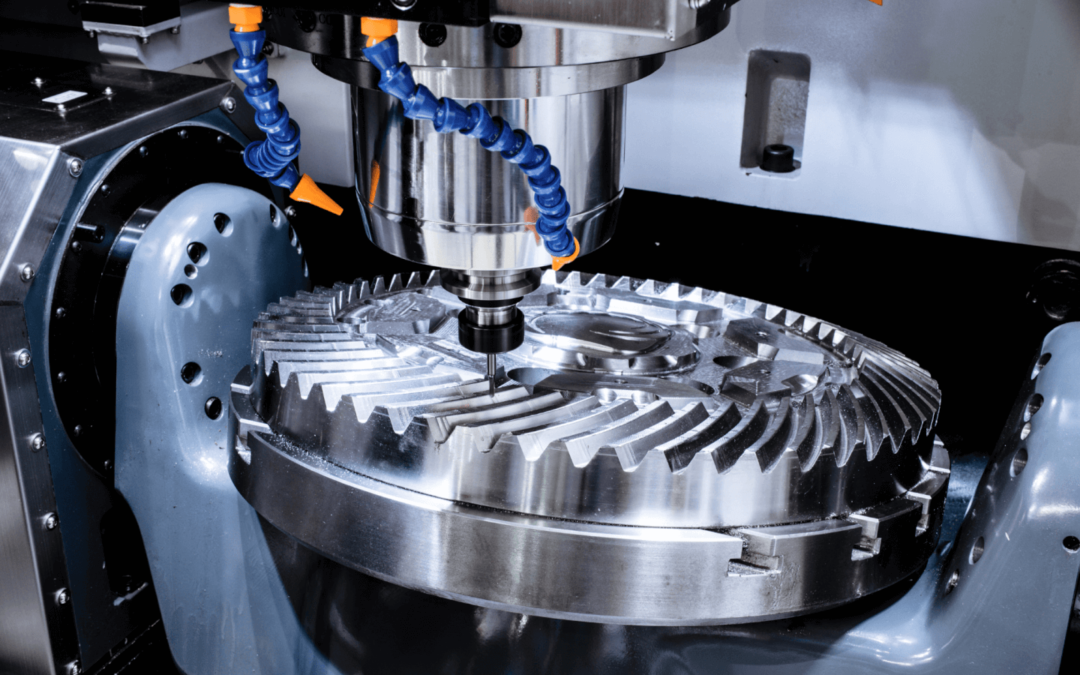

Lifting a milling machine is a task that demands special attention to detail and utmost caution. Entrepreneurs and business leaders often require moving such machines either within their facilities or to different locations, making it a critical operation for their production and operational efficiency.

This article explores the intricacies involved in how to lift a milling machine, ensuring that safety and efficiency are prioritized. With the right techniques, not only can you prevent potential damage to the machine, but you can also protect those involved in the process.

Understanding the Importance of Proper Lifting

The Risks Involved

Lifting a milling machine improperly can be dangerous. The machine may become damaged, or even worse, those involved in the move can be injured. Potential risks may include impacts from the machine tipping over or nerves and muscles strains from improper lifting techniques.

Benefits of Proper Lifting Techniques

By adopting the appropriate procedures, you improve safety, protect your machinery from damage, and maintain productivity. Products like the DripX Leak Detection System showcase similar principles in ensuring efficiency and reliability.

Preparation and Planning

Assessing the Weight and Size

Before any attempt to move the machine, it is critical to determine its size and weight. Most machine manuals provide this information, crucial for deciding the lifting method.

Choosing the Right Equipment

Depending on the size and weight, select the right equipment for the job. This might include cranes, forklifts, or hoists specifically designed for such machines. You can read about milling machines for more detailed information.

Step-by-Step Lifting Guide

Inspecting the Area

Ensure that the working area is clear from obstructions. A clean and clutter-free area provides a safer environment for the lifting operation.

Positioning the Equipment

Align the lifting equipment with the loads center of gravity. This helps in maintaining balance throughout the lifting operation.

Ensuring Proper Strapping

Use strong and durable straps or chains. Double-check knots and fittings to prevent slippage. Quality connections are akin to the effectiveness of systems like WaterX in preventing leaks.

Executing the Lift

Lift the machine slowly and steadily. Quick, sudden movements can lead to loss of balance and increase the risk of accidents.

Cautionary Tips

Use Trained Personnel

Ensure that those involved in the lifting process are trained and equipped with the right skills. Familiarity with the equipment and the components of the machine is essential.

Follow Manufacturer Recommendations

Always adhere to the guidelines set by the manufacturer for safe lifting. Remember, these machines are precision tools designed with specific risks acknowledged by their developers.

Post-Lift Analysis

Inspect for Damages

After the move, inspect the milling machine for any apparent damages or misalignments. This proactive approach prevents production hitches and machine faults.

Review and Report

Every lift should end with a review of the process. Evaluate what went well and areas that need improvement, ensuring both immediate remedies and future preparedness.

Frequently Asked Questions

What Tools Are Best for Lifting a Milling Machine?

Depending on the machine’s weight and size, forklifts, cranes, or hoists are ideal tools. Choose equipment suitable for your specific milling machine.

Can a Milling Machine Be Moved Without Lifting Equipment?

While smaller machines might be maneuvered without heavy equipment, larger and heavier machines should always involve professional lifting tools for safety.

How Often Should Lifting Equipment Be Inspected?

It is advisable to inspect lifting equipment before every use. Regular checks ensure that the equipment remains in prime condition and any signs of wear or potential failure are addressed promptly.

Conclusion

Successfully lifting a milling machine involves preparation, right equipment selection, and adherence to safety protocols. Prioritize the welfare of both the machinery and personnel involved. With informed planning and execution, you ensure that your operations remain seamless across different environments. For more insights on machine operations, consider visiting Direct Machines Blog.

This article contains affiliate links. We may earn a commission at no extra cost to you.