Building your own CNC milling machine can be an immensely rewarding project. Not only does it give you a deeper understanding of these amazing machines, but it also saves a considerable amount of money compared to buying one. Learning how to build your own CNC milling machine might seem challenging at first, but with a step-by-step approach, it becomes manageable. In this article, we’ll delve into the specifics, ensuring you have the knowledge to succeed.

Why Build Your Own CNC Milling Machine?

Constructing a personalized CNC milling machine offers numerous benefits. First, it provides the opportunity to customize your machine to fit specific needs, enhancing its functionality. Second, it fosters hands-on learning and deepens your comprehension of CNC technology.

Gather the Necessary Materials

1. Basic Components

You’ll need fundamental parts like a frame, spindle, motors, and a control system. Sourcing high-quality components can enhance the machine’s efficiency.

2. Tools and Equipment

Essential tools include drills, saws, screwdrivers, and wrenches. Additional specialized equipment may also be required depending on the design specifics.

Designing Your CNC Milling Machine

3. Frame Design

The frame is the backbone of your machine. Ensuring it’s sturdy and well-designed is vital for accuracy and precision while machining.

4. Selecting the Right Software

Choose software that aligns with your CNC needs. The software should be user-friendly and compatible with your machines hardware.

Assembling the Machine

5. Building the Frame

Start by building the frame. Ensure all joints are secure and level. Any misalignment can affect the machine’s precision.

6. Installing the Motors

Attach the motors carefully, as they drive the machine. Proper installation is key to ensuring smooth operation.

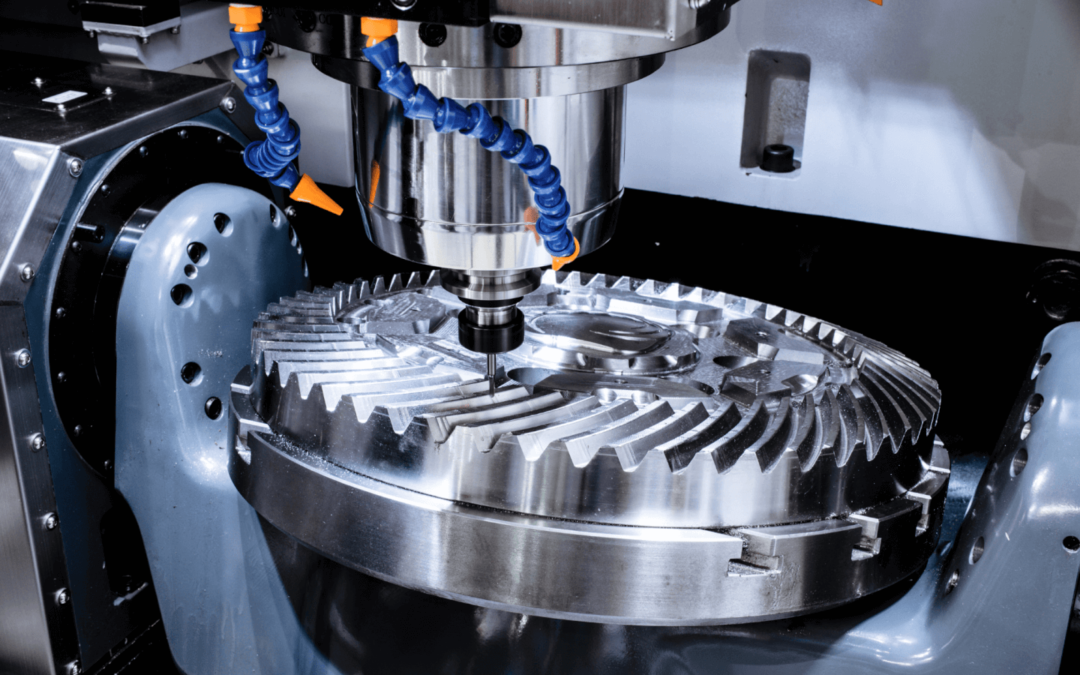

7. Installing the Spindle

The spindle is a crucial component; its installation requires precision for efficient cutting.

Setting Up the Electronics

8. Wiring the Control System

Properly wire the control system components. This step is critical for controlling the machine accurately.

9. Testing the Electronics

Before using the CNC machine, conduct thorough testing to confirm all electronics function correctly.

Calibrating Your CNC Milling Machine

10. Precision Calibration

Calibration is essential for maintaining accuracy. Spend time fine-tuning the machine to ensure it performs optimally.

11. Software Calibration

In addition to physical adjustments, make sure the software is configured correctly to communicate with your hardware.

Troubleshooting Common Issues

12. Addressing Mechanical Failures

Common issues can arise. Understanding these problems helps in swift troubleshooting and repairs.

13. Electrical Troubleshooting

Electrical issues can impede machine function. Regular maintenance can help prevent these problems.

Enhancing Your CNC Milling Machine

14. Upgrading Components

Consider upgrading parts for increased efficiency and precision as you grow more comfortable with your machine.

15. Software Upgrades

Keeping your software up to date ensures continued compatibility and performance improvements.

FAQs

What is the benefit of building a CNC machine?

Building a CNC machine allows customization and cost savings, offering personal learning and adaptability.

How difficult is it to assemble the machine?

The difficulty depends on your experience, but with detailed instructions and proper tools, it is manageable.

Can I use any software for my CNC machine?

It is crucial to choose software compatible with your hardware, ensuring seamless operation and control.

For more insights into DIY CNC machines and their configurations, you can visit The Engineering Choice.

Additionally, check out this innovation in IoT technologies that could inspire further technological creativity in personalized CNC applications.

This article contains affiliate links. We may earn a commission at no extra cost to you.