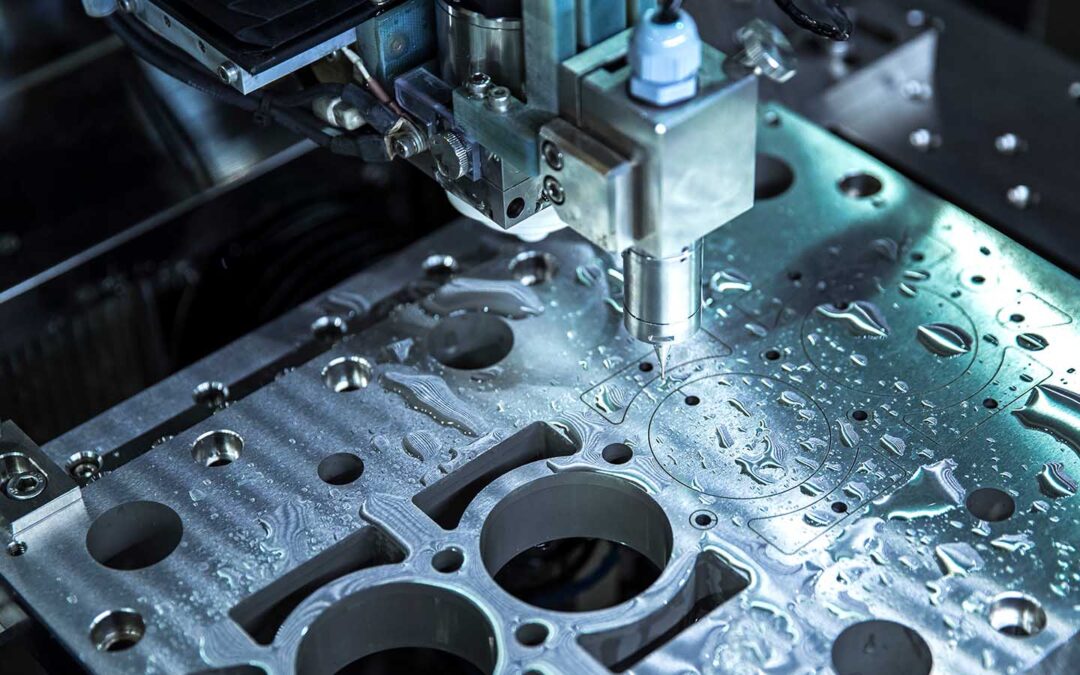

Boring a cylinder, particularly with a milling machine, is a fundamental task in many workshops. Understanding how to bore a cylinder with a milling machine not only enhances your machining skills but also ensures precision and the smooth functioning of mechanical parts. Let’s delve into the details of this technical yet rewarding machining process.

Understanding the Basics of Cylinder Boring

The process of boring involves enlarging a hole that has already been cast, drilled, or forged. In our case, a milling machine is used for this purpose. This technique is essential for maintaining accurate diameters and achieving a smooth finish.

The Role of a Milling Machine

A milling machine is a versatile tool that boasts numerous applications, including boring. Its ability to move in several dimensions allows for precise operations, crucial in milling machine movement.

Why Use a Milling Machine for Boring?

Milling machines are preferred due to their precision and versatility. They can perform uniform cutting thanks to their multi-directional movement capabilities.

Essential Tools and Materials

Before beginning the boring process, gather the necessary tools: the proper milling machine, an appropriate cutting tool, measuring tools like calipers and micrometers, and safety gear.

Selecting the Right Cutting Tool

Ensure your cutting tool is sharp and compatible with your machine and workpiece. The correct tool ensures efficiency and precision.

Preparing the Milling Machine

Before you start, it’s crucial to prepare your milling machine. Clean the workspace, check the machine’s alignment, and ensure all components are functioning perfectly.

Step-by-Step Guide to Boring a Cylinder

- Start by aligning the cylinder on the machine table.

- Use precision measuring tools to ensure the cylinder is set to the desired specifications.

- Secure the workpiece tightly to prevent any movement.

- Choose the appropriate boring tool and adjust the speed settings according to the material of the cylinder.

- Begin the boring process by starting the milling machine at a consistent speed.

- Monitor the progress and make necessary speed adjustments to maintain precision.

- Once the desired diameter is achieved, halt the machine and check for accuracy with measuring tools.

Common Mistakes in Cylinder Boring

Even experienced machinists can make errors. Some frequent mistakes include improper alignment, not checking machine calibration, and inappropriate speed settings.

How to Avoid Machining Errors

Preventing errors is crucial. Regular maintenance of the machine, proper setup, and consistent monitoring during the operation are essential practices.

Maintaining Your Tools and Machine

A well-maintained machine ensures longevity and accuracy. Regularly check for wear and tear and replace any faulty components immediately.

Cleaning and Storage

After completing the boring process, clean the machine thoroughly. Proper storage practices can significantly enhance the lifespan of your tools and machine.

Applications of Cylinder Boring

Boring cylinders is essential in various industries, from automotive to manufacturing. It’s crucial for ensuring the smooth operation of engines and industrial machinery.

Exploring Further Machining Techniques

Mastering cylinder boring is just the beginning. Consider diving into other techniques such as facing, drilling, and more to enhance your machining prowess.

For more details on different types of milling machines, refer to this comprehensive guide.

FAQs

Q1: What size milling machine is recommended for cylinder boring?

A1: It depends on the size of the cylinder. For general use, a medium-sized machine should suffice. For guidance, see our size recommendation.

Q2: Can I use a drill press instead of a milling machine?

A2: While possible, a drill press lacks the precision of a milling machine. However, for alternative methods, view cylinder boring with a drill press.

Q3: How often should the milling machine be calibrated?

A3: Regular calibration is essential. It’s best to calibrate before each major project or at least quarterly to maintain accurate performance.

This article contains affiliate links. We may earn a commission at no extra cost to you.