An asphalt milling machine is a vital piece of equipment in the construction industry, mainly used to remove old pavement layers and prepare roads for repaving. Understanding its functioning can give entrepreneurs and business leaders insight into its significance and operational efficiency. Knowing how does an asphalt milling machine work is crucial for businesses involved in large-scale infrastructure projects.

Introduction to Asphalt Milling Machines

The process of asphalt milling involves the removal of the surface layer of asphalt. The milling machine grinds and removes existing asphalt pavement, allowing for surface leveling and smoothness. It ensures that the pavement is ready for a new layer of asphalt, ultimately leading to the renovation of roads with minimal environmental impact and resource consumption.

Importance of Asphalt Milling in Construction

Asphalt milling is crucial because it allows for the efficient recycling of road materials. By reutilizing the milled asphalt, companies can save costs and reduce waste, increasing the sustainability of their operations. It is also an essential step in road repairs, allowing for the gradual replacement of damaged asphalt without replacing the entire structure.

Components of an Asphalt Milling Machine

An asphalt milling machine is composed of several vital components:

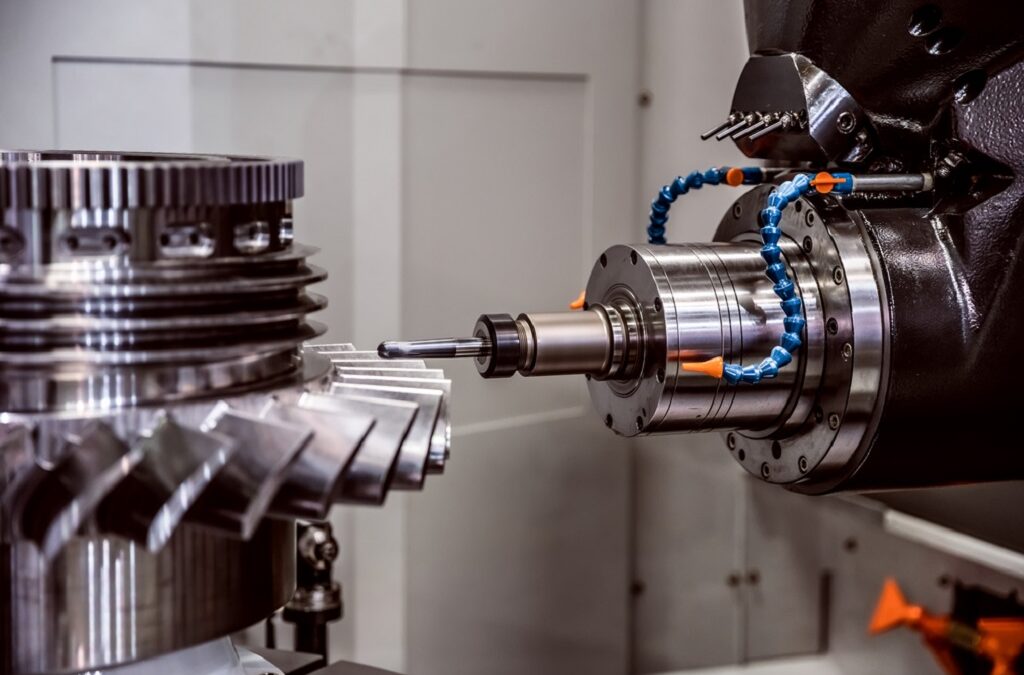

- Drum Cutter: This is the most critical part of the machine. It rotates and mills the asphalt layer, removing it efficiently.

- Conveyor System: The milled material is collected by the conveyor belt and transported into trucks for recycling or disposal.

- Hydraulic System: This system adjusts the cutting depth, making sure the exact amount of asphalt is removed as required.

Milling Process Overview

The milling process begins with the alignment of the machine following the existing road structure. The operators then adjust the machine’s settings according to the desired milling depth. As the machine moves forward, the drum rotates and removes the top layer of asphalt. The conveyor system ensures that the milled material does not obstruct the operation, providing a clear path for continued milling.

Step-by-Step Process

- Preparing the site by removing debris and setting clear traffic guidance.

- Positioning the milling machine and adjusting cutting depth.

- Starting the milling drum and engaging the conveyor system.

- Executing the milling by guiding the machine along the predetermined path.

- Collecting and transferring the milled material for reprocessing.

- Smoothing and cleaning the milled surface.

Once the milling is completed, operators will conduct further site preparation, removing any loose material, ensuring the area is ready for the next layer of asphalt.

Types of Asphalt Milling Machines

Understanding the types of milling machines used in various projects can significantly influence how businesses plan their operations.

- Half-lane Milling Machine: Typically used in highway projects to efficiently manage significant areas.

- Small Milling Machine: Suited for smaller projects like parking lots, urban areas, and patching operations.

Choosing the Right Machine

When selecting a milling machine, entrepreneurs must consider the following factors:

- Project Size and Scope: Determines whether a large or small machine is suitable.

- Surface Material: Different machines handle varying materials with different efficiency rates.

Technological Advancements in Asphalt Milling

Recent technological advancements have significantly impacted asphalt milling, with many machines now incorporating features like laser steering and automatic grade control, which enhance precision and reduce the possibility of human error. These enhancements significantly increase project efficiency and accuracy.

Challenges in Asphalt Milling

While benefits are numerous, challenges also exist, such as:

- Environmental Factors: Weather conditions can heavily impact operations.

- Machine Maintenance: Regular maintenance and check-ups are necessary to avoid unexpected downtime, which can halt projects.

Asphalt Milling and Environmental Impact

Milling reduces carbon footprint by reusing asphalt and requires less energy compared to complete road reconstruction. This environmentally friendly approach not only conserves resources but also minimizes project costs.Read more about how technology is optimizing sustainability in various fields.

Cost-Benefit Analysis of Asphalt Milling

Businesses often encounter significant savings and improved returns on investment with milling. While initial costs can be high, milling conserves buying new materials as well as significantly reduces future repair costs, making them a worthwhile investment.

Conclusion

Asphalt milling is a vital and economically prudent choice for modern infrastructure projects. Understanding how does an asphalt milling machine work and leveraging the technology effectively can lead to substantial operational and financial benefits for businesses in the construction industry.

FAQ

What is the life expectancy of milled asphalt?

Milled asphalt typically lasts for many years, depending on weather conditions and the quality of reapplication.

Can asphalt milling be done in rainy weather?

Milling is generally best avoided during heavy rain to ensure machine efficiency and accuracy.

What is done with milled asphalt?

Milled asphalt is often recycled, reducing costs and environmental impact by reusing the material in new projects. This process is a testament to the industry’s ongoing commitment to innovative and eco-friendly practices.

This article contains affiliate links. We may earn a commission at no extra cost to you.