What is a Gib on a Milling Machine: Essential Guide for Precision?

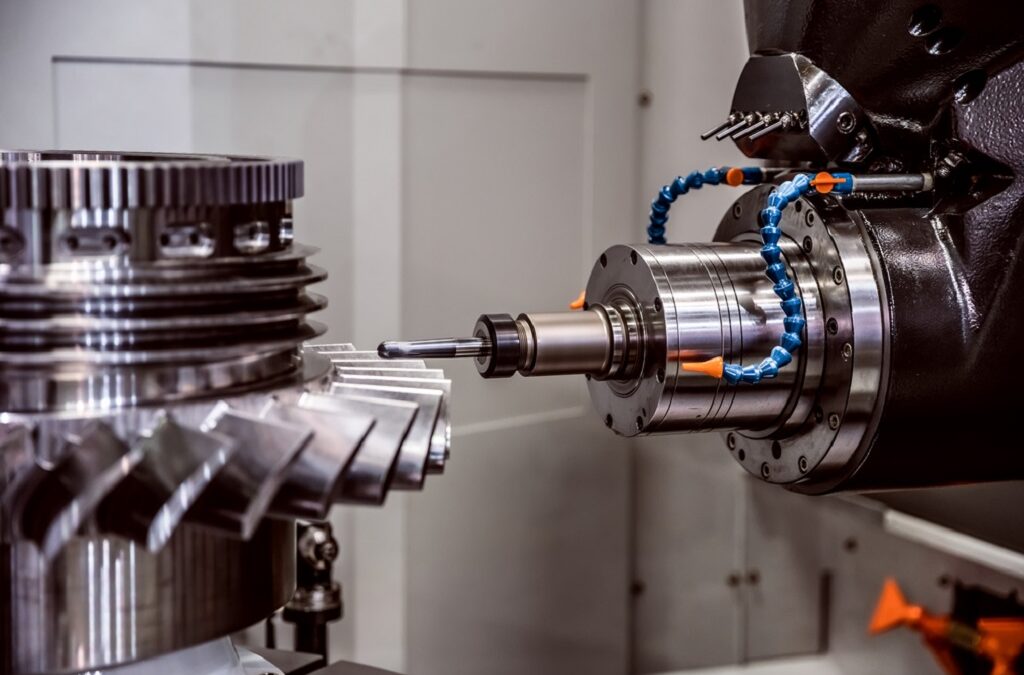

Understanding what is a gib on a milling machine is key for those in industries relying heavily on precision machinery. A gib is a crucial component in milling machines, which are commonly used in manufacturing environments.

The Role of a Gib in Milling Machines

In essence, a gib helps maintain the accuracy and alignment of moving parts within a milling machine. Its primary function is to provide a precise guide path, allowing for smoother operation. If you wish to enhance the performance of your milling equipment, you can explore more about milling components at varieties of milling machines.

How Gibs Improve Precision in Milling

Gibs are often adjusted using set screws, which ensure that the working parts of the milling machine remain stable. Their meticulous adjustment is vital, as loose or poorly adjusted gibs can reduce precision and cause wear on other machine components.

Types of Gibs Used in Milling Machines

There are several types of gibs used in milling machines, including tapered gibs and straight gibs. Each type serves a unique purpose, contributing to the uniqueness of a given milling machine’s function and capacity for precision work.

Tapered Gibs vs. Straight Gibs

While tapered gibs allow for easier adjustment and fitting, straight gibs are simpler in structure, offering straightforward functionality. The choice between them often depends on specific manufacturing needs and the design of the milling machine.

Historical Development of Milling Machine Gudgeons

The evolution of milling machines and their components, such as gibs, reflects the advances in industrial precision and automation. Innovations within this arena continue to propel modern manufacturing processes, as discussed in this comprehensive overview of milling machinery.

Modern Innovations in Gudgeon Design

Today’s gibs are designed with advanced materials and precision engineering, allowing for more efficient and effective operations. These innovations contribute to the enhanced durability and functionality of milling machines.

Challenges with Gib Maintenance

While the role of gibs is to maintain precision, they require regular maintenance to function effectively. Proper maintenance protocols can prevent alignment issues and prolong the lifespan of milling equipment.

Common Issues with Gudgeons

Common issues include wear and tear and incorrect adjustments. These problems must be carefully monitored and addressed promptly to prevent any adverse impact on machine performance.

The Future of Milling Machine Components

The future looks promising for milling machine components as technological advancements continue to drive innovation. The development of more durable, user-friendly, and precisely engineered gibs will further refine the milling process.

Emerging Trends in Milling Technology

One emerging trend is the integration of IoT and ML to enhance machine learning capabilities for predictive maintenance and error detection. For instance, components discussed in the IoT revolution reflect a larger trend towards interconnected machine systems.

FAQs

What is a gib on a milling machine?

A gib is a mechanical component that ensures the stability and alignment of moving parts within a milling machine.

How does a gib work?

It works by acting as a precise guide path, maintaining the smooth operation of the machine’s moving parts through careful adjustment.

Why is gib maintenance important?

Without regular maintenance, a gib can become misaligned or worn, which could degrade the accuracy of the milling machine and lead to costly repairs.

This article contains affiliate links. We may earn a commission at no extra cost to you.